Melbourne Engineering Solutions & Certification

With decades of caravan industry experience on staff and a large design portfolio to our credit, MESC have seen it all when it comes to caravan and trailer design and compliance.

We specialise in chassis analysis, testing and compliance to ADR62, with our custom testing apparatus and test data collection equipment designed to ensure the highest quality tests are performed with comprehensive data to back up the results.

We can also provide advice on all other areas of VSB1, to help you ensure that your caravan or camper trailer is fully compliant with ADRs.

Why MESC?

Our team is one of the most experienced and sophisticated in the industry.

MESC is the consolidation of engineering, design and certification expertise developed by Track Trailer (TRACK) over more than 20 years. TRACK is a technical leader and one of the most highly respected manufacturers in the Australian Recreational Vehicle (RV) manufacturing industry.

This capability has already placed TRACK in the top echelon of it’s market for the performance and durability of its technically advanced products.

TRACK is a long-term member of RVMAP (Recreational Vehicle Manufacturing Accreditation Program) and is very proud of its exemplary compliance record and engagement with compliance issues and regulation changes.

Our Services

MESC combines a range of services, helping you to take your design from concept to reality in a safe and compliant manner.

Design

Using the latest CAD software and experienced engineers and designers, MESC can create comprehensive computer models of your design.

These models can then be used for analysis and validation prior to physical testing, this will not only help to improve your design, but also potentially save money on failed tests or failed products.

Designs need not be limited to structural components, we have the capability to design a range of components or products, specialising in sheet metal.

Analysis

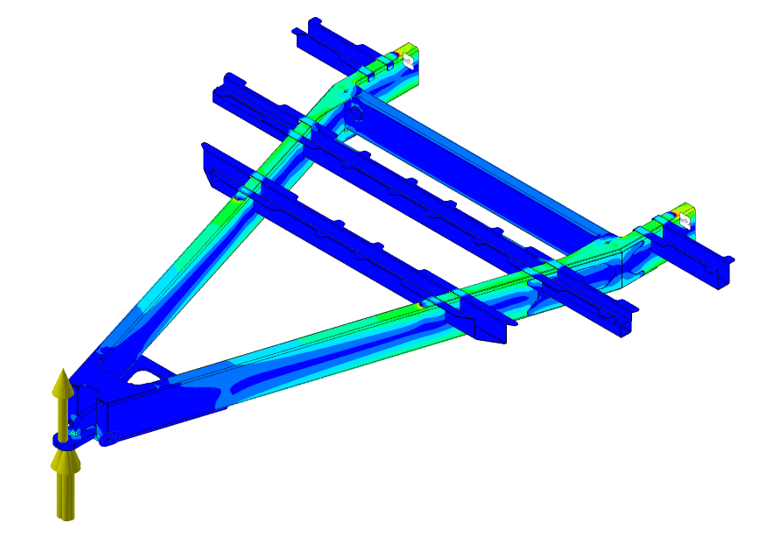

Prior to chassis construction and subsequent physical testing, MESC can conduct extensive finite element analysis to identify weaknesses in a design to either reduce or eliminate via further design or to provide information useful when performing subsequent physical testing.

Identification of chassis ‘hot spots’ during FEA will guide placement of strain gauges during physical testing. Comparing these results validates the computer model and provides assurance of chassis compliance.

Testing capabilities extend beyond ADR required loadings and can be used to analyse other chassis and suspension components.

Testing

Physical testing of chassis and chains can be done to ensure compliance with ADR62.

Using a test rig developed in 2012-2013 for testing Australian Defence standards including trailer helicopter lifting points, recovery points and tie down points, a substantial testing apparatus has been designed to hold down a typical caravan chassis and complete the static drawbar and chain testing required in ADR62 for trailers less than 4.5T.

We are able to apply loads at the point of coupling and chains up to 10T. This can be done on all of the 3 required axes.

Further to this MESC has the equipment to test a variety of components including proving ground testing.

Certification

MESC has developed extensive tests and checklists and can produce compliance assessments against the requirements VSB1.

Using computer modelling all required viewing angles for lighting and reflectors can be analysed and visualized.

Staff have extensive experience with the requirements of VSB1 and can assist with preparation of documentation to effectively demonstrate compliance with VSB1, linking back to the ADRs which underpin VSB1.

Get Professional Advice

Contact our MESC team to discuss your design and testing needs using the form below.